Lamilux

Continuous Rooflight

Skylight solutions for large light incidence

LAMILUX Continuous Rooflight Systems

Energy-efficient building lighting made easy

By using continuous rooflight systems, you save on constant costs that would incur for the operation of artificial lighting systems. In addition, the building owner creates great added value for the people who spend time in the building. More daylight enters the inside and thus increases the sense of well-being. Continuous rooflight systems are particularly suitable for large flat roofs, as a large-scale skylight system can then be installed. A continuous rooflight system consists of many perfectly matched individual components. As a result, it does not only serve to illuminate a building, but also as a natural ventilation and smoke and heat extraction system. An individual concept can be created according to your needs and wishes. For this purpose, 3 basic variants are generally available: Continuous Rooflight B in arched design, Continuous Rooflight B in Passivhaus standard and the Continuous Rooflight S in ridged roof design. In addition, the product portfolio also includes the Translucent Façade and Roof, which is optimally suited for walls and renovations, and the Continuous Rooflight S energyline with photovoltaic systems.

When choosing an energyline product, you do not only permanently reduce energy costs, but also produce your own electricity at the same time. This is particularly sustainable and should be considered in times of climate change. Ventilation and smoke/heat extraction flaps that can be integrated into every continuous rooflight provide optimum smoke extraction and ventilation of the building. At LAMILUX you will find the right solution for every need.

Choose your suitable continuous rooflight system

Incidence of light in industrial, storage or sports halls

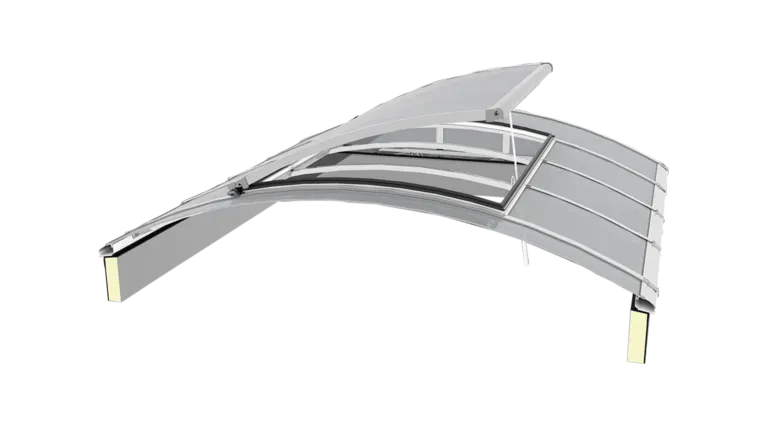

Continuous rooflight arched

First in the world with certified watertightness under heavy rain and storm conditions

Perfect thermal insulation

Environmental product declaration according to DIN EN 15804, DIN EN ISO 14040, DIN EN ISO 14044 and EN ISO 14025

BIM - ready - download at bimobject.com

Compliance with European standards for snow and wind loads

Fire spread is prevented by linear burn-through protection

The benefits at a glance

Energy efficiency

- NEW: First Continuous Rooflight on the market with tested air tightness up to class A according to ETA 09/0347

- Integrated, modular system which consists of many perfectly matched and innovative individual components

- Perfect heat insulation with European approval for use

- The internal and external metal components, both in the load-bearing structure and in the flap systems, are completely thermally separated from one another

- Use of the isothermal load converter (ITL) – a component for the use of material with excellent heat insulation properties at the anchor point

- Composite glazing with extremely low thermal transmittance coefficients

- LCA made easy: For our Continuous Rooflight B there is an comprehensive product declaration according to ISO EN 15804

Stability

- NEW: design snow load up to 4.4 kN/m² (according to Eurocode)

- NEW: with our GFUP glazing, a composite material made of glass fibres and polyester resin, we achieve hail resistance class HW5 according to the VKF guideline

- Thanks to our Composites Division and the associated expertise, our GFUP glazing is particularly resistant to UV radiation, weathering and chemically aggressive emissions

- The world's first Continuous Rooflight with audited watertightness under heavy rain and storm (DRI 3.0 m/s²)

- Our Continuous Rooflight B is BIM-ready - download at bimobject.com

- Extremely stable when open guaranteed by spring-loaded multiple joint traverses connected directly to the flap construction

SHEV

- NEW: SHEV and ventilation drive now also available as 48 volt motor

- Effective ventilating action with the Smoke Lift Continuous Rooflight B (DIN EN 12101-2), as a double or single flap

- In case of fire, they are quickly opened by means of thermal release, thermal and CO2 remote release or electric remote release

- All smoke and heat exhaust systems can also be combined with ventilation systems

Safety

- Fall-through-proof during installation, valid for 1 year after manufacture

- Optional: permanent fall-through protection can be ensured by various systems

- We maintain professionally and regularly for you

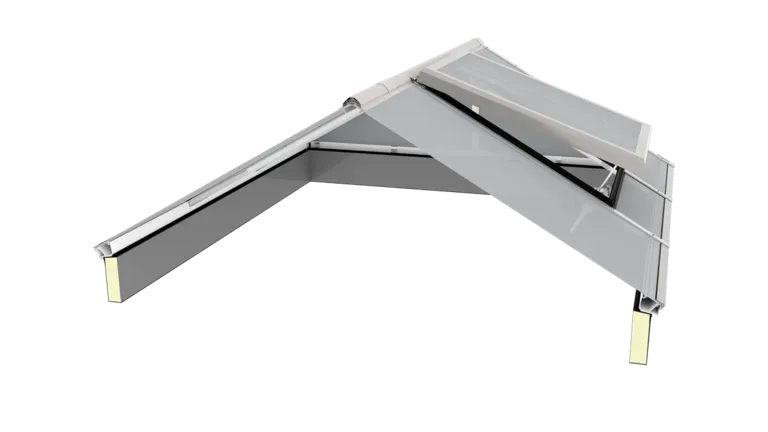

Continuous rooflight ridged roof

First in the world with certified watertightness under heavy rain and storm conditions

Completely thermally separated construction due to technical cleverness

Environmental product declaration according to DIN EN 15804, DIN EN ISO 14040, DIN EN ISO 14044 and EN ISO 14025

Resistant to snow and wind loads

Fire spread is prevented by linear burn-through protection

The benefits at a glance

Innovation

- The world’s first Continuous Rooflight with certified watertightness in heavy rain and during storms (DRI 3.0 m²/s)

- The use of cutting-edge materials ensures that the product is completely thermally separated to meet the highest energy efficiency standards for modern industrial and administrative buildings

- Due to innovative system components, the Continuous Rooflight can withstand the strongest wind and snow loads

- Wide range of glazing options

- Glazing surfaces are available with 30° or 45° incline

- Design: Northern light shed roof with and incline of 30° on the rear of the shed and an incline of 60° on the northern light

Energy efficiency

- Mullion and transom construction and flap systems are thermally separated

- Isothermal Load Converter (ITL) – a component designed to incorporate highly thermally insulating materials in the base profile

- Composite glazing adapted to building-specific energetic requirements (panel thickness between 10mm and 32mm) with low heat transmission coefficients of up to 1.2 W/(m²K)

- High energy-saving daylight incidence and configurable solar heat input

- Energy-efficient, natural ventilation

- Life cycle assessment made easy: There is a comprehensive Environmental Product Declaration for the Continuous Rooflight S in accordance to ISO EN 15804

Safety

- Bionically Dynamic Tensioning Technology (BDT) in the ridge area for flexible force/ tension compensation in the event of heavy wind and snow loads

- Active Expansion Absorber (AEA) for absorbing expansion differences between seals and tensioning belts in the glazing bars

- Dynamic Torque Control (DTC) to ensure perfect tensioning and secure mounting of the glazing in the flap systems

- Modular flap systems in various sizes for perfectly dimensioned smoke extraction areas

- Linear Burn-through Protection (LBP) to prevent the spread of fire on the roof

- Integration of smoke and heat exhaust ventilation systems (SHEVs) and SHEV control panels

Design

- The structure features a ridged roof design which is appealing from an architectural point of view

- Modern overall impression, innovative construction

Translucent Façade and Roof

Perfect thermal insulation

Completely thermally separated construction due to technical cleverness

Very high stability of the opened flap systems due to multi-joint crossbeams

Secondary seal for tightness of larger areas

The benefits at a glance

Energy efficiency

- Perfect thermal insulation with General Building Approval

- Modular overall system consisting of numerous, perfectly coordinated and innovative single components

- The interior and exterior metallic components in the supporting structure as well as in the flap systems are completely thermally separated from each other

- Composite glazing with lowest heat transmission coefficient

- All glazing variants achieve the highest airtightness class according to EN 12207 (up to class 4)

Stability, safety and SHEV

- Effective ventilation effect with the Smoke Lift W | R (DIN EN 12101-2), as tandem-serial

- Fast opening in the event of fire due to thermal triggering, thermal and CO2 remote triggering or electric remote triggering

- All smoke and heat exhaust ventilation units can also be combined with ventilation systems

- Highest stability of the flap systems in open position through spring-mounted multi-joint traverses

- We provide professional, regular maintenance

Tested and certified

General Building Approval:

German cross reference

General Building Approvals (ABZ) are issued by the German Institute of Building Technology (Deutsches Institut für Bautechnik – DIBt). This certificate verifies that a construction product meets the technical requirements for its use.

LAMILUX Quality Certificate – This certificate provides proof that our skylights are consistently manufactured and implemented in accordance with product approvals and the technical standards specified in the approvals. We keep our promises.

Test certificates and european technical approvals

- Thermal protection properties tested in accordance with EN ISO 10077-1

- Watertightness tested in accordance with EN 12208

- Airtightness tested in accordance with EN 12207

- Fire behaviour of the glazing classified according to EN 13501-1

- Melt-out verified in accordance with DIN 18230-1

- Single and double flap systems of the smoke and heat exhaust ventilation systems are tested and classified in accordance with EN 12101-2

Downloads

Daylight, fresh air

and fire safety

in industrial constructions

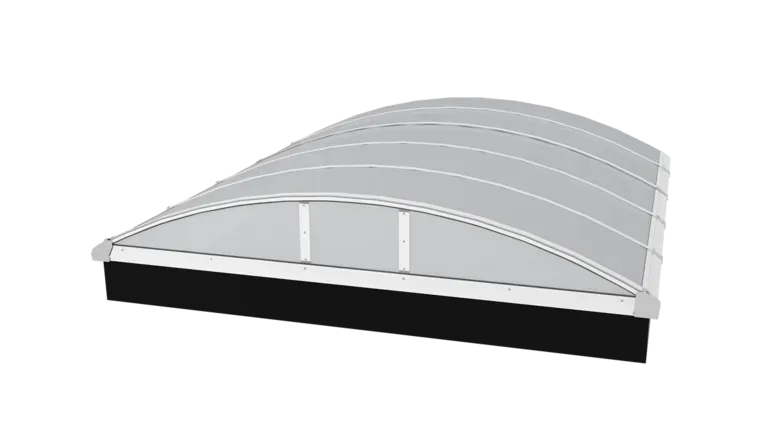

Continuous Rooflight Passivhaus Standard

First in the world with certified watertightness under heavy rain and storm conditions

First continuous rooflight certified to Passivhaus standard

Passivhaus efficiency class phB

Thermal bridge-free system with kink-free isothermal curve

Environmental product declaration according to DIN EN 15804, DIN EN ISO 14040, DIN EN ISO 14044 and EN ISO 1402

Fire spread is prevented by linear burn-through protection

The benefits at a glance

Certified energy efficiency

- The world’s first Passivhaus certified Continuous Rooflight system

- Passivhaus efficiency class – phB

- Heat transmission coefficient (USK): 0.95 W/(m²K)

- Overall system with flawless isothermal lines and free of thermal bridges

- Thermal performance values calculated based on DIN EN ISO 10077-1 and 10077-2

- Life cycle assessment made easy: There is a comprehensive Environmental Product Declaration for the Continuous Rooflight B Passivhaus in accordance with ISO 14025 and EN 15804 (EPD - modules A1 - D)

Stability and security

- The world’s first Continuous Rooflight with certified watertightness in heavy rain and during storms (DRI 3,0 m²/s)

- Based on European Technical Approval ETA-09-0374

- Complies with European standards regarding snow and wind loads

- Thermal protection properties tested in accordance with ETAG 010

- Watertightness tested in accordance with ETAG 010

- Burn-through safety verified in accordance with DIN 18234-3

- Melt-out verified in accordance with DIN 18230-1

- Permanent fall-through protection grid

Downloads

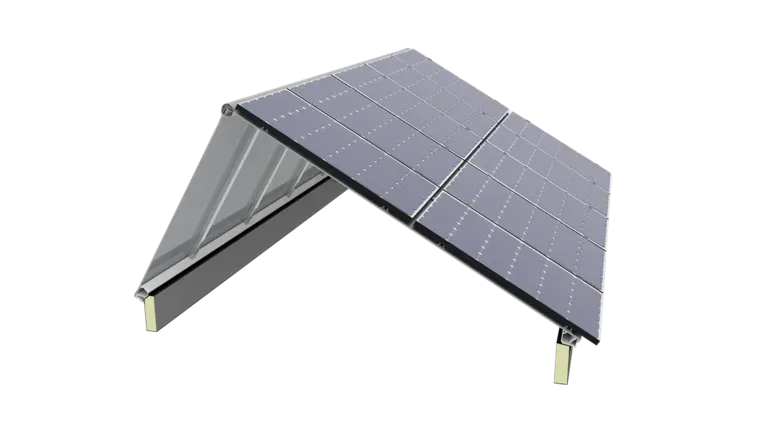

Continuous Rooflight Ridged Roof Design with Photovoltaics

Combination of environmentally friendly photovoltaic modules and continuous rooflight systems

First in the world with certified watertightness under heavy rain and storm conditions

Resistant to snow and wind loads

Environmental product declaration according to DIN EN 15804, DIN EN ISO 14040, DIN EN ISO 14044 and EN ISO 14025

Fire spread is prevented by linear burn-through protection

The benefits at a glance

Continuous Rooflight S

New

- Combination of skylight and green energy generation through sophisticated photovoltaic modules

- Northern light shed roof with 30° incline of the PV, opaque rear of the shed roof and 60° incline in the northern light side: This allows you to take advantage of the optimum sun angle of 30° (other dimensions available on request)

- The world’s first Continuous Rooflight with certified watertightness in heavy rain and during storms (DRI 3.0 m/s²)

- The use of cutting-edge materials ensures that the product is completely thermally separated to meet the highest energy efficiency standards for modern industrial and administrative buildings

- Due to innovative system components, the Continuous Rooflight can withstand the strongest wind and snow loads

- Wide range of glazing options

Energy efficiency

- Mullion and transom construction and flap systems are thermally separated

- Isothermal Load Converter (ITL) – a component designed to incorporate highly thermally insulating materials in the base profile

- Northern light side: Composite glazing adapted to building-specific energetic requirements (panel thickness between 10mm and 32mm) with low heat transmission coefficients of up to 1.2 W/(m²K)

- Energy-efficient, natural ventilation

- Life cycle assessment made easy: There is a comprehensive Environmental Product Declaration for the Continuous Rooflight S in accordance with ISO EN 15804

Safety

- Bionically Dynamic Tensioning Technology (BDT) in the ridge area for flexible force/ tension compensation in the event of heavy wind and snow loads

- Active Expansion Absorber (AEA) for absorbing expansion differences between seals and tensioning belts in the glazing bars

- Dynamic Torque Control (DTC) to ensure perfect tensioning and secure mounting of the glazing in the flap systems

- Modular flap systems in various sizes for perfectly dimensioned smoke extraction areas

- Linear Burn-through Protection (LBP) to prevent the spread of fire on the roof

- Integration of smoke and heat exhaust ventilation systems (SHEVs) and SHEV control panels

Design

- The structure features a ridged roof design which is appealing from an architectural point of view

- Modern overall impression, innovative construction

Downloads

New technologies

for the future

of sustainable construction

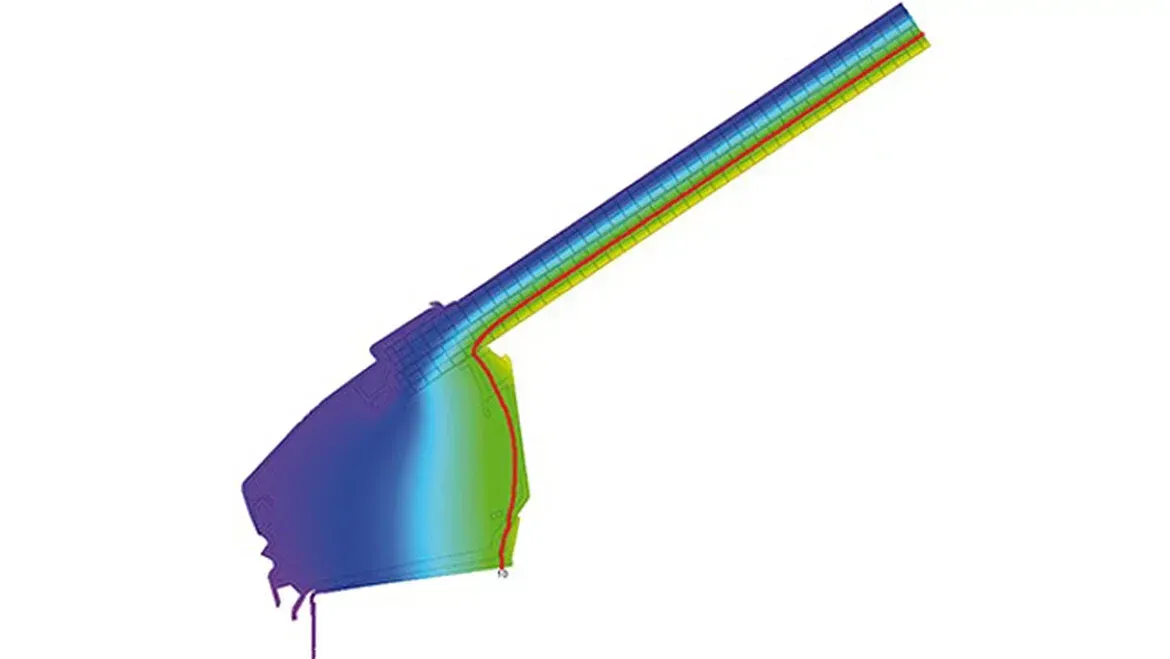

Isothermal curves without a weak point

Systems with optimised energy performance of buildings

Our demand: products that make a significant contribution to the optimised energy management of your building. Because old and often inadequately renovated buildings often have a considerable energy loss. Weak points - such as windows and doors - in the building shell are the main contributors to this. Building components such as windows or doors tend to form thermal bridges at critical points such as frame areas or fastening materials. A typical phenomenon that can then be observed: In winter, flat windows start to tarnish on the inside at the edge of the pane. Condensation forms more easily at these points, leading to the development of mould. This cannot be assessed by means of the U-value though, but by means of isothermal curves that are simulated by calculation, or by means of thermal images that are documented on the finished object.

To save valuable energy and at the same time minimise the risk of condensation and health-endangering mould formation, thermal bridge-free constructions are indispensable. This is because condensation occurs wherever the construction has a weak point. To exclude weak points, all components of the continuous rooflight systems must interact optimally in terms of energy. There are various standard conditions for checking and verifying this.

Foot profile

DIN 4108-2 for "Thermal Insulation and Energy Saving in Buildings" sets out boundary conditions for a thermal insulation verification. In addition to using the atmospheric conditions actually prevailing on site, the standard stipulates minimum evidence for 20°C indoor air temperature and -5°C outdoor air temperature. These parameters can be used to determine isothermal curves for the building components. When evaluating the isotherm course, in particular the course of the 10° - curve is analysed, since condensation occurs at a relative humidity of 50%. As long as the 10° isotherm runs over the entire building component and the structure connections within the construction, no condensation is to be expected. Here, the surface temperature is strongly dependent on the components used. At LAMILUX, the glazing with the lowest U-value already fulfils the requirement of the 10°C isotherm. The good energy efficiency properties of our continuous rooflight systems have been tested and proven in accordance with ETAG 010.

The LAMILUX Smoke Lift for Continuous Rooflight B and S

Safety with smoke and heat extraction systems with simultaneous natural ventilation

If a fire has broken out in a building, immediate action must be taken. The LAMILUX Smoke Lift for Continuous Rooflight B and S is indispensable in cases like this, as it ensures that escape routes are cleared of smoke. Why is this important? The fire and smoke gases produced by a fire are harmful to health and machinery and in the worst case can quickly lead to death. With SHEVS that open automatically in case of fire smoke, an important step has been taken towards meeting the protection goals according to DIN 18232. These protection goals include the protection of people, property, and the environment. Personal protection involves securing escape routes to enable rapid exit from the building. If the smoke layer temperature is below 250° C, there is no risk to persons from radiating heat. Property protection means reducing the impact of fire. This is to prevent the building from being completely filled with smoke and possibly collapsing. It is also intended to ensure that the fire and smoke gases cool down as quickly as possible. This prevents a sudden flash-over, i.e., the sudden change from incipient fire to full fire, which becomes very dangerous within a few minutes. The last protection goal, environmental protection, is achieved by supporting and facilitating fire brigade operations. As a result, qualified extinguishing attempts are started with less use of extinguishing agents and less extinguishing damage.

The smoke lift for our continuous rooflight systems is available in various designs, such as a single flap, a symmetrical or asymmetrical double flap and a tandem serial single flap.

Reference project Lebenshilfe Schweinfurt

Lebenshilfe in Schweinfurt with a total of seven Continuous Rooflights S installed in various lengths. In addition, three fall-through grilles to go with them, seven smoke and heat extraction systems and five Glass Skylights F100 were installed.

Reference project VW dealership Gdansk Poland

VW dealership in Poland with four installed Continuous Rooflights B and one Rooflight F100 with Smoke Lift. In addition, two Glass Roof systems PR60 with a total area of approximately 90 m² were installed.